Post-Pandemic Procurement: 4 Things Your Organization Should Consider

As organizations prepare for post-pandemic life, many are still strategizing for what normal will look like and procurement is no exception. COVID-19 has caused fractures across supply markets, labor markets, and the global supply chain. Procurement leaders are now tasked with the challenge to find the solution of how their organization and function will need to evolve to keep pace with the changing times.

Over the last 18 months, procurement has emerged to be at the forefront of key industry strategies. Organizations have transitioned the business function from tactical cost cutting support to integral strategic component that drives financial success, mitigates risks, and supports long-term prosperity. The conversation rapidly moved from cost savings to ensuring that organizations have abundant supply of essential commodities and services that are critical to business operations. Below are four key priorities that procurement organizations have implemented to help position their businesses for success in the post-COVID world.

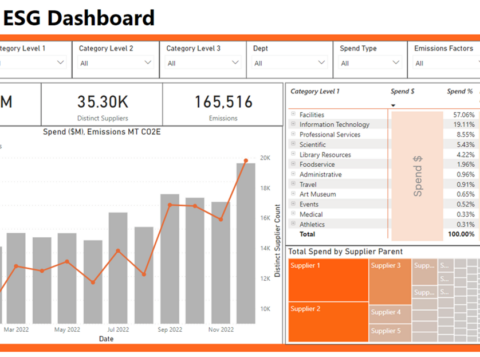

Acceleration of the Procurement Digital Roadmap

When organizations think of a Digital Roadmap, they rarely think about procurement, but that is rapidly changing. The pandemic put reliance on the shift towards digital platforms and innovation, most which saw wild success, to maintain the business continuity. However, core procurement did not change much. For best-in-class organizations, a digital roadmap that supports procurement leaders in deploying technology enablers to maximize the efficiency and output across the entire Source-to-Pay (S2P) process is critical. A well thought out Procurement Digital Roadmap is an immediate priority to increase efficiency, free up resources, eliminate the risk of manual errors, and unlock overall value for the organization. Key features of a procurement digital roadmap are:

- Data Visualization & Management: Transforms data into user-friendly, executive-friendly, visual formats that can simplify decision making by organizing information and delivering strategic actionable insights and recommendations.

- Predictive and Advanced Supply Market Analytics: Combining modeling, statistics, machine learning, and artificial intelligence with multiple third-party data sources to predict most likely scenarios for cost/price fluctuations, supply market challenges, demand, inflationary expectations, and supplier/country risks, etc. to promote proactive decision making.

- Robotics Process Automation: Software that recognizes and learns patterns and can perform rule-based tasks. This process is used to automate multiple repetitive manual tasks, driving efficiency and reducing errors and risks in execution.

- Intelligent content extraction: Uses Optical Character Recognition (OCR) and learning algorithms to read unstructured documents such as PDFs of contracts, specification drawings, and Bills of Material, and rapidly extract critical pieces of data

- Cognitive computing/AI: Leverages pattern recognition software and iterative machine learning algorithms to rapidly categorize unstructured spend, cost, contract, and supplier data (e.g., raw AP records/T&E systems extracts) to deliver new insights and opportunities.

- Blockchain: This cryptologic data structure uses a trusted peer-to-peer network to create digital transaction ledgers which can verify and validate transactions in the P2P process (or any other supply chain process) and then be used to trigger automated payment.

Supplier Collaboration and Resilience

Supplier Solvency was, and continues to be, a major concern. As the economy slowed down, supplier supply chains and cash flow struggled. The overreliance or lack of diversity across a supply base could create a potential operational bottleneck that may have major impact on a business in the event of solvency challenges.. Procurement executives need to prioritize re-examining partnerships with their key suppliers and deploy strategies to diversify their supply chain and ensure transparency across their supplier base.

- Vertical Integration: Partner with suppliers to evaluate additional business opportunities up the delivery chain to deliver savings and economies of scale

- Risk Management: Perform a risk audit with preferred and secondary suppliers and partner to mitigate gaps, supply challenges, and liquidity concerns

- Supplier Financial Support: Develop financial support partnerships for struggling suppliers through creative payment structures or shared success programs

- Alternative Sources of Supply: In areas where supplier is operating at a competitive disadvantage, consider shifts to alternative suppliers to supplement current option

Unlocking Value – Transform from Tactical to Strategic

There has been immense pressure on Procurement to implement cost savings strategies and reduce the expense burden as a percentage of revenues. The global economic impact throughout the pandemic and, now an expected inflationary environment, has and continues to make it even more difficult to maximize savings from vendor relationships – they are facing a similar struggle to manage raw material costs as well as preserve revenue. As the economy picks back up again, it is still anticipated that demand will lag recovery as companies remain on a crunch. Procurement’s mission for the foreseeable future will be to extract value despite these circumstances. Given these challenges, there are several ways to unlock value and continue to drive profitability.

- Champion Zero-Basing – With changes in supply and demand, it is important to continuously reevaluate each spend category to assess opportunities to create value

- Modernize Contract Structures – Leaders should instill greater risk management within each contract structure, implementing terms that will foster growth and protect from future downside.

- Monitor Results – Partner with Finance and IT departments to develop accurate picture of utilization and savings generation to ensure informed decision making

- Embrace Technology – Utilize S2P technology to incorporate market intelligence in supplier selection, augment resource productivity, and automate activities such as invoice processing

Invest in Your People

The Procurement operating model was forced to be reimagined during the pandemic. But, was the resulting operation actually efficiency, productive, and the best for the future of the departments? Technology has enabled the work-from-home model to succeed and maintain productivity. Although we’ve been able to maintain continuity, fatigue is becoming prevalent. Employee health is critical to continued successful operations. That being said, there is no ‘one size fits all model’ for what the new normal will look like. Organizations need to revisit how they want to operate in the future and allow operations and collaboration to take many shapes. Time is now to realign the operating model to what works best for their business and workforce.

- Modernization of Roles and Responsibilities – Establish responsibilities that best streamline value creation through greater expertise within procurement, more technology within accounts payable, and more tools within sourcing.

- Employee Check-Ins – Institute regular touch points with workforce, focusing on mental, physical, and emotional health

- Evaluate Supplier Collaboration Tools – Maximize investment in digital collaboration technologies and assess products that facilitate both remote and on-site workers

- On-site vs. Remote – Assess individual roles to determine which jobs can be performed remotely and provide the infrastructure to support

Post Pandemic Procurement is here. While the four priorities are not exhaustive of all issues that Procurement leaders are tackling, they represent critical items that will need to be addressed for resilience beyond the pandemic. While there is still a good deal of uncertainty for what the next year will look like, Procurement leaders have opportunity platform to evolve their organization and elevate the role of Procurement to a critical profitability driver for their company.