Manage Your Packaging Costs: Reduce, Reuse & Recycle

With the combination of an inflationary environment, increased demand for products, reduced supply, changing company cultures and increased customer expectations, most miss that packaging is a conduit across all these challenges. In short, packaging is preparing for a time to change.

One of the biggest reasons for the growth of packaging is eCommerce. The eCommerce channel grew 40% year-over-year from 2020 to 2021. Teams do not have a lot of time to focus on packaging, but given the expected increase in material costs and the pressure to use packaging as a product and brand differentiator, it should be a major focus area for businesses as we head into 2022.

While most businesses understand the reasons behind skyrocketing transportation costs and manage them actively, when it comes to material costs, the increases have been even more pronounced and less managed. Over the last 12 months, both virgin and recycled resins have seen massive price increases due to increased demand and limited supply as a result of production disruptions. Recycled resin pricing had traditionally tracked virgin resin pricing, but because of the change in the demand patterns based on requirements from large retailers to have more recycled product, the pricing for the two spot markets has now decoupled. Paper-based products have seen a similar story. U.S. paper mills have a high demand for mixed paper, largely due to the uptick in e-commerce, and there is a major shortage for paperboard and Old Corrugated Containers (OCC) due to increased demand for e-commerce and in-store orders.

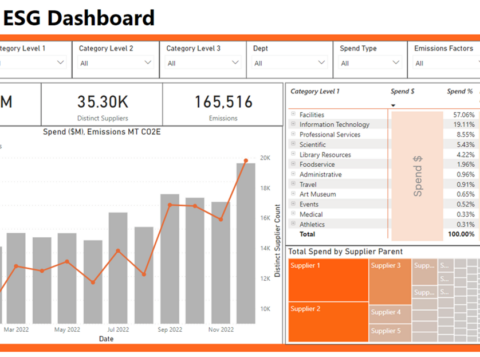

In the past, price was the only factor in making product decisions, but companies are increasingly being driven by their commitments to sustainability in their decision making. This change is driven by an increased awareness, corporate ESG goals, and conscious customers. According to a 2021 Global Buying Green Report for packaging, 67% of consumers consider it important that products have recyclable packaging materials. These environmental factors like surging costs of shipping, transportation and packaging materials, coupled with the increased importance of company image have forced companies to think more critically about smaller packaging, recycled and recyclable material, and sustainability in the short and long run.

The continued rise of e-commerce is challenging businesses to differentiate their product offering through packaging. Beyond the simple need of getting goods to customers effectively, brands are tied to the look, feel, and structure of their packaging. There are businesses that have elected to ship more “air” in an emphasis to have standard packaging and having a consistent customer experience through e-commerce. Others have made a choice to use the lowest cost packaging and bet that their product differentiation is sufficient enough for customer engagement and do not view packaging as a component of that. With the rising costs and the pressure of sustainable packaging, an opportunity exists to differentiate products through packaging. This need has now set a drastic necessity for procurement teams to be involved and engaged in managing the packaging category strategy.

How has your packaging team adapted to these changes? Here are 3 initiatives that AArete has employed for its clients’ packaging needs:

- Recyclable Packaging: Move towards packaging material that promotes increased usage of recyclable material. This helps not only in having a more sustainable packaging solution, but also allows recouping some of the costs by selling them to recycling companies. For example, AArete recently assisted a large home goods company in diversifying their packaging supply base to add in suppliers with recyclable packaging options for their void filling solutions. Additionally, these vendors also helped replace their plastic bubble wrap with other recyclable options.

- Strong Reverse Logistics Process: Ensure that companies have the best reverse logistics contracts in place. This practice can help your company take advantage of the demand for recyclable materials by reselling your unused product. In one case, AArete helped a discount retailer earn an additional $3M annually by renegotiating their reverse logistics contracts for OCC.

- Commodity Price Intelligence: Conduct recurring analyses of raw material indices to adjust for price changes. AArete has helped several large transportation companies evaluate their purchasing strategy for commodity-based products by implementing a pricing model that reflects historical and future price changes in raw materials compared to the total cost of the products. By tracking paper and plastic indices actively, AArete was able to develop a purchasing strategy to generate more than 12% savings for one of its transportation clients.